1) Complete vacuum forming solution

2) ABS, smooth, gloss or textured

3) Applicable to custom plastic processing

1. Application of ABS plastic thermoforming technology

With the rapid demand of more diversified products, more and more designers have been considering to use vacuum forming technology to make their custom plastic processing, plastic parts, covers and etc, which features low tooling cost and fast lead time.

Vacuum forming, one of the oldest methods of processing plastic material, has also been widely used today to make plastic enclosure, cover, cowl, housing, parts, base, liner, tray, tub, container, case, dome, box, rack, stand, inner liner, component, fitting, accessory, applied in wide industries as Automotive, Agricultural, Building and Construction, Design, Electronic, Machinery, Sanitary industries and etc.

2. Why chooose Honyien Plastics Company for

ABS plastic thermoforming service?

A. Proficient skills and profound knowledge in dealling with thick gauge plastic sheet vacuum forming, up to 12mm;

B. Competitively pricing, because of self-supply of vacuum forming material: plastic sheets;

C. Seamlessly cooperation with customers to ensure exact fulfillment of all specification.

D. Complete vacuum forming solution: from preliminary project design support, material production to tooling design, making and vacuum formed products manufacturing

E. All types of vacuum forming material available: ABS, HIPS, ABS/PMMA, etc. textured, smooth, gloss or matt, fire-retarded or UV resisted

3. Process of contracted ABS plastic vacuum forming manufacturing with Honyien:

A. CAD/3D File Review--The process begins with preliminary review of your design file. To see if your design files are fit for thermoforming technologies, please contact us for first review.

B. Design Assessment--Your design will be thoroughly examined by our assessment team to see how we can best make it with vacuum forming. Proposals will be offered while keeping the best quality and maintaining the integrity of your design to the greatest extent.

C. Product Design Assisting--Our engineer will assist you fulfill your creation, make proposals, translate your drawing into CAD/3D files, if necessary.

D. Tooling--Tight control will be made over the entire tooling process to eliminate the risk of misinterpretation of your concept and other potential problems.

E. Sampling--Quick and accurate sampling will follow to confirm your designs before mass vacuum forming production.

F. Manufacturing--Our thermoforming manufacturing features fast lead time, exceptional level of details, flexible order volumes.

4. ABS plastic vacuum formed process at Honyien:

1. Extruding plastic sheet: | ABS, HIPS, PP, PE, PC, PETG, PMMA resin granules are extruded or co-extruded into thermoplastic sheet--textured, smooth, gloss or matt, fire-retarded or UV resisted |

2. Vacuum forming to shape: | After being heated, the plastic sheet is stretched onto or into a mould, and held against the mold by applying vacuum between the mould surface and the sheet to form desired shapes. |

3. Cooling to maintain shape: | Once formed the plastic need to cool before being released from the mould. To speed up the cooling cycle, fans are fitted and activated once the plastic part is formed. |

4. Making large product: | Our machine could be restructured to make larger plastic vacuum forming products, with maximun dimensions of 3000*2000*800*12mm (L*W*H*T) |

5. Trimming edges: | Extra material is firstly trimmed before more accurate processing. Sawing is often used in this stages. Polishing is made additioanlly to smoothen the edges. |

6. Drilling holes: | Drilling oftens follow the trimming. Other post forming processes include decoration, printing, strengthening, reinforcing and assembly. |

7. CNC Processing: | For more accurate and faster speed post thermoforming processing, CNC is often used. The machine is computer programmed to select the correct cutting tools and angle to suit each cutting area. |

8. Examination and checking: | Before packaging, all our vacuum forming samples and products will be carefully checked in terms of dimensions, surface finish, stenghth, colour requirements and so on. |

9. Cleansing and Packaging | All vacuum forming products are cleaned before packaging. Products are wrapped with plastic film to prevent scratches and cartoon boxs are used or other methods are applied as required. |

-------------------------------------------------------------------

If you have project to do, what you should give us ?

1, file format:

3D:igs, prt , step, stp, sld.

2D:.dwg .cdr .pdf .ai, other pictures format.

2, we usually use the software

Pro-e (3D)

Solidworks (3D)

Rhinoceros() (3D)

3dmax (3D)

UG (3D)

Autocad (2D)

Photoshop (2D)

Coreldraw (2D)

Adobe Illustrator(2D)

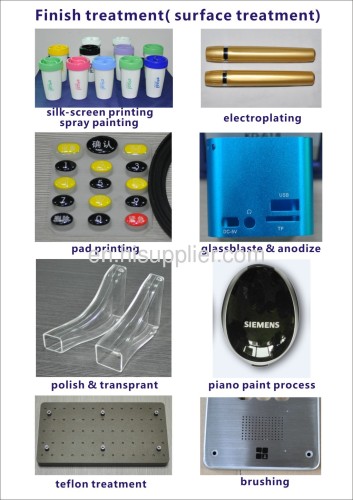

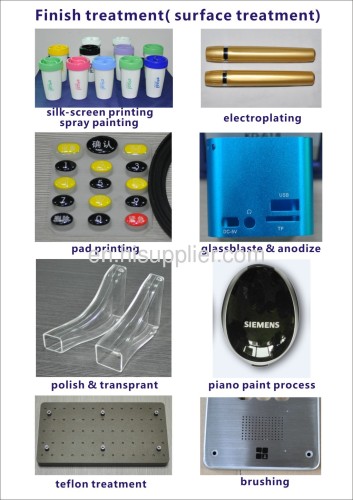

3, finish treatment(surface treatment)

If you need finish treatment(surface treatment),such as painting, screen printing, anodizing, glass blasted, pad printing, electroplating, oxygenation, brushing, etc. please give us the details as possible as you can. Such as the colors( with Panton numbers or CMYK&RGB numbers), the size of glass, the size and the location that you want to print, etc.

If you don`t know how to prepare them, please contact us for help.

Contact us:

Address:2F,Bldg.C,Fufang S&T Park, Fuyong Town, Baoan District, Shenzhen, Guangdong, China

Tel: +86-755-27150460

Fax: +86-755-27658255

M.P.:+86-15999640890

E-mail:gavin @carful.net

MSN:carful @live.com

Skype: gavin.cwh

Website:carful. com. cn; prototype-cn. com

-------------------------------------------------------------------

Gift for the business cooperation

CARFUL owned an another company that called "Carful Auto Accessories (Shenzhen) Co., Ltd.", we produce many excellent products such as Bluetooth car kit, universal hands-free mount,etc.(carful. cn).Every customer that cooperated with us in

Rapid Prototyping and CNC processing project can

get a gift from "Carful Auto Accessories (Shenzhen) Co., Ltd."

-------------------------------------------------------------------

our factory

-------------------------------------------------------------------

our equipment

-------------------------------------------------------------------

customers and cooperation

We have lots of customers in Europe, America, Japan and South Korea and every parts of China. Such as Siemens, Philips, Nokia, Parrot,etc.

Meanwhile, CARFUL also cooperates with some domestic companies, associations, and foreign counterparts about academic exchange, sharing the technological achievements, to keep our technical ascendant, and established a good bridge for the both sides.

-------------------------------------------------------------------

faithful service and low price, keep secret for customers:

Realize your ideas; we assure your excellence with low cost!

Over 10 years` experience, perfect after-treatment handwork!

Carful Co., Ltd. was found in 2002, adhering to the spirit of "professional, high-quality, efficient, honest ", after recent years of exertion and innovation, we has developed into a professional and experienced company that include

metal and plastic model making, rapid prototype making, small batch processing, Reverse Engineering,product and structure design, etc.CARFUL will provide you with high quality guarantee, Efficient and competitive quotation, Your satisfaction is our greatest achievement!

Also we will keep secret for you strictly, we can sign contract separately for it.

We can accept the payment : 50 % upfront and 50% before shipment by sending photos for confirmation. So it will reduce the risk for your cooperation with us.

-------------------------------------------------------------------

What can we do?

Service and application

Carful can provide you the rapid and satisfactory service in the field of product design, prototype making, batch processing. Meanwhile we can meet your requirement of different materials, processing technology and industries.