High precision Mini SLA rapid prototyping

1) Precise machining with smooth and clean surface

2) High efficiency of product processing in appearance

3) Tolerance :0.01mm

High precision Mini SLA rapid prototyping

High precision Mini SLA rapid prototyping

Specifications | 1, Towell CNC plastic rapid prototypes 3,High quality and precision with favorable price 4, Customized sample manufacturing and Fabrication service |

Service we provide | 1,CNCplastic prototypes/Metal prototypes 2, SLA/SLS plastic rapid prototypes 3, Vacuum casting (Silicone mould) 3,Automotive/Medical/Household prototypes 4, Design service (OEM service) |

Machine Equipment Introduction | 1, At TOWELL we have over 15 industry leading CNC machines. These top quality machines work by processing 3D data. CNC can be used to produce machined parts and prototypes very quickly, at a high production rate and to a high degree of accuracy 2, CNC machines are able to work with a great many different materials including; plastics (ABS/PC/POM/PP/PVC/PMMA etc.), metals (Stainless steel, Aluminum etc) wood and other specialist materials. 3, There are a number of benefits to using CNC from variety of materials available, the strength and accuracy of the finished product, the materials used are strong and durable therefore very good for testing and CNC processing process is relatively cheap. We are able to offer some of the highest quality CNC machined products at very competitive prices. 4, Our CNC machines have a maximum size capacity of 1800mm×680mm×120mm per item. |

Quality Control | At TOWELL we have numerous measures in place to ensure our products meet and exceed our client's requirements and expectations. We provide a 3 stage quality inspection check 1, After the part has been machined it is checked against the drawing specifications 2, Before and after the finishing department has painted and polished the part it is inspected 3, The manager will personally check the products before they are packaged and sent for shipping We are also happy to work according to the level of QC our customers require, this could be: single, multiple or pre-shipping inspections, raw material testing/inspection or start to finish quality control. Constant updates will be relayed to the customers via their dedicated customer service representative. |

Shipping | TOWELL can support all logistical requirements. We use reliable companies that offer excellent service to get your products to you on time anywhere in the world. We provide the client with the reference so they can keep track of their products until they arrive safely with them. |

Terms of payment | 50% T/T in advance, balance paid before delivery or Paypal. |

Package | Bubble, foam , carton ,wooden case etc |

-------------------------------------------------------------------

If you have project to do, what you should give us ?

1, file format:

3D:igs, prt , step, stp, sld.

2D:.dwg .cdr .pdf .ai, other pictures format.

2, we usually use the software

Pro-e (3D)

Solidworks (3D)

Rhinoceros() (3D)

3dmax (3D)

UG (3D)

Autocad (2D)

Photoshop (2D)

Coreldraw (2D)

Adobe Illustrator(2D)

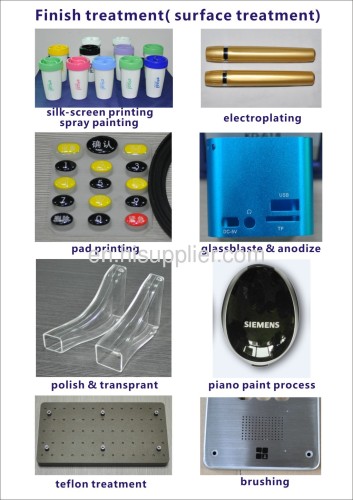

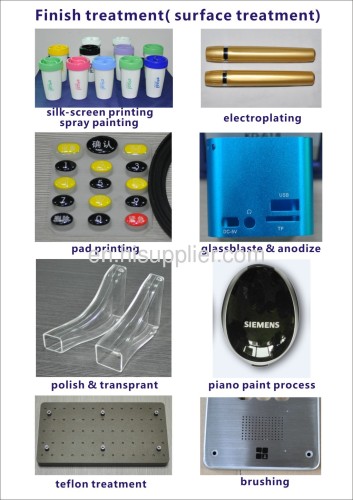

3, finish treatment(surface treatment)

If you need finish treatment(surface treatment),such as painting, screen printing, anodizing, glass blasted, pad printing, electroplating, oxygenation, brushing, etc. please give us the details as possible as you can. Such as the colors( with Panton numbers or CMYK&RGB numbers), the size of glass, the size and the location that you want to print, etc.

If you don`t know how to prepare them, please contact us for help.

Contact us:

Address:2F,Bldg.C,Fufang S&T Park, Fuyong Town, Baoan District, Shenzhen, Guangdong, China

Tel: +86-755-27150460

Fax: +86-755-27658255

M.P.:+86-15999640890

E-mail:gavin @carful.net

MSN:carful @live.com

Skype: gavin.cwh

Website:carful. com. cn; prototype-cn. com

-------------------------------------------------------------------

Gift for the business cooperation

CARFUL owned an another company that called "Carful Auto Accessories (Shenzhen) Co., Ltd.", we produce many excellent products such as Bluetooth car kit, universal hands-free mount,etc.(carful. cn).Every customer that cooperated with us in

Rapid Prototyping and CNC processing project can

get a gift from "Carful Auto Accessories (Shenzhen) Co., Ltd."

-------------------------------------------------------------------

customers and cooperation

We have lots of customers in Europe, America, Japan and South Korea and every parts of China. Such as Siemens, Philips, Nokia, Parrot,etc.

Meanwhile, CARFUL also cooperates with some domestic companies, associations, and foreign counterparts about academic exchange, sharing the technological achievements, to keep our technical ascendant, and established a good bridge for the both sides.

-------------------------------------------------------------------

faithful service and low price, keep secret for customers:

Realize your ideas; we assure your excellence with low cost!

Over 10 years` experience, perfect after-treatment handwork!

Carful Co., Ltd. was found in 2002, adhering to the spirit of "professional, high-quality, efficient, honest ", after recent years of exertion and innovation, we has developed into a professional and experienced company that include

metal and plastic model making, rapid prototype making, small batch processing, Reverse Engineering,product and structure design, etc.CARFUL will provide you with high quality guarantee, Efficient and competitive quotation, Your satisfaction is our greatest achievement!

Also we will keep secret for you strictly, we can sign contract separately for it.

We can accept the payment : 50 % upfront and 50% before shipment by sending photos for confirmation. So it will reduce the risk for your cooperation with us.

-------------------------------------------------------------------

What can we do?

Service and application

Carful can provide you the rapid and satisfactory service in the field of product design, prototype making, batch processing. Meanwhile we can meet your requirement of different materials, processing technology and industries.

Product design

1. RE(reverse engineering). the experienced engineers uses precision laser measuring instrument to capture the design data of one product, then complete the design of products.

2. ID(Industry Design). Through market research and analysis, we will keep constantly communicating with customers, Screening, and improving, until we get a good idea that adapts to the market and the consumer.

3. MD(Mechanical Design). On the basis of full understand of the product`s functions, compliance to appearance design, reference to the size and form of various components, we determine the most reasonable structure design.

Prototype making

The classic ideas and reasonable structure, must be ultimately verified by prototype and model. Carful uses the required materials, with the process of

CNC machining, laser rapid prototyping etc. and many technology such as grinding, polishing, fuel injection, screen printing, pad printing, laser engraving, sandblasting, electroplating, oxidation, drawing, the UV, relief etc. to complete the verification of the appearance, structure or function of your design.

1.Analyzing by processing methods, we can process the following prototypes and models :

CNC plastic prototype: with the material of: ABS, acrylic, PP, PC, POM, nylon, wood, etc;

CNC metal prototype: with the material of:aluminum, aluminum - magnesium alloy, aluminum - zinc alloy, copper, steel, iron, etc;

Rapid Tooling: rapid metal tooling, silicone molding, low-pressure pouring mould

Hand-carved making: with the material of: fatlute, foam, plaster, and so on.

2. Analyzed by application, we can process the following prototypes and models :

automobile components prototypes: automobile and motorcycle parts, car dashboard, shade and other parts;

medical devices prototypes: x-ray, blood dialysis device, monitor, foot care boxes

Household appliances prototypes:such as color TV, air conditioning, electric fans, electric oven, monitors, kettles, coffee makers, electric fans, electric cooker, juicer, Blender, etc.

Digital telecom prototypes:such as mobile phones, telephones, fax machines, doorbell, cameras and others

Small batch processing

In industrial production, because of the different processes, costs, quantities, there are many parts that can`t use mass production by machines, which require a certain special technology to manufacture them with small batch. also they may need manual processing. We mainly use CNC to do the small batch processing.

1. Small batch processing of plastic parts , with the material: POM, ABS, transparent acrylic (commonly known as PMMA), PC;

2.

Small batch processing of metal parts, with the material: aluminum, aluminum - magnesium alloy, aluminum - zinc alloy, copper, steel, iron, etc.

High precision Mini SLA rapid prototyping

High precision Mini SLA rapid prototyping