Shenzhen metal precision cnc milling

1, Introduction (Shenzhen metal precision cnc milling)

Material: aluminum /steel/ copper

Color: natural color anodizing

Appearance: no sink marks, burn marks

2, Image (Shenzhen metal precision cnc milling)

3,Brief Description

11 years experience in Design, Prototype, Manufacture, 3, 4, 5 axis cnc machining;

Do as your drawing or request ;

High efficiency of product processing

Low volume production/ Small batch processing;

Well and High Quality Control;

Prompt Delivery;

OEM manufacturer;

Customer's Designs and Logos are Welcome;

Competitive Prices.

,

Item NO. | CNC milling |

Materials | Iron, aluminumsteel, copper, plastic,carbon steel, nylon, bronze, solder alloy, HSS, tool steels, or as per thecustomers' requirements. |

Specification | cnclathe processing can be produced as per customer's drawings and requirement. |

Available format | 3D: .IGS/.STP/.X_T/.PRT/.STL/.SLDPRT 2D:Auto CAD,.DWG/.DXF/.PDF |

Surface treatment | Heat treatment, polishing, galvanized, electroplating, spraying, and paintingand so on. |

Advantage | Rich experience in manufacturing CNC lathe processing;Professional team; Fine workmanship; Appearance with bright color andluster; Competitive price with good quality; Eco-friendly CNClathe processing; Short lead time; Customer Satisfaction Service. |

Processing equipments | CNC machining center, CNC lathe, grinding machine, automatic lathemachine, conventional lathe machine,milling machine, drilling machine,EDM, wire-cutting machine, CNCbending machine etc. |

Service project | To provide production design, production and technical service, moulddevelopment and processing, etc. |

Testing machine | Digital Height Gauge, caliper, Coordinate measuring machine, projectionmachine, roughness tester, hardness tester and so on. |

Minimum order quantity | negotiable |

Delivery Detail | according to the QTY of the order |

Payment | T/T 50% deposit ,and cash 50% before shipment |

Packing | Plastic bags; outside packing: Standard export carton Products can bepacked according to customers' request. |

Business scope | CNC center machining, drilling, turning, grinding, tapping, mould designand processing, casting, sheet metal workingetc |

Application | Automation machine, medical device, industrial machine, automobile,electric appliance, and other industries. |

Quality Control | 1. we review the 3D drawing from client. If the 3D drawing files doesnot meet the demand of rapid prototyping process, our businessman willcommunicate with you in time to improve the drawing. 2. We ensure regular maintenance for equipments used in themanufacturing process and testing accuracy. 3. All process have tracking testing to ensure we produce all productsin dimensional accuracy requirement. we will do our best for all stagesincluding packaging and shipping, 4. follow-up service willbe provided after the prototype is received to ensure it meets customerexpectations. |

Our service | 1. excellent in quality andmoderate in price; 2.Fastdelivery time; 3.11 years professional experience;

4.Weuphold the principle of integrity to offer the best service. |

Exported Country | Japan, America , Belgium ,Britain , Canada , Netherlands etc. |

Remarks | No parts are in stock, for customization only! Any RFQ, please feel freely to send your drawings (CAD or ProE) forquotation. |

-------------------------------------------------------------------

If you have project to do, what you should give us ?

1, file format:

3D:igs, prt , step, stp, sld.

2D:.dwg .cdr .pdf .ai, other pictures format.

2, we usually use the software

Pro-e (3D)

Solidworks (3D)

Rhinoceros()(3D)

3dmax (3D)

UG (3D)

Autocad (2D)

Photoshop (2D)

Coreldraw (2D)

Adobe Illustrator(2D)

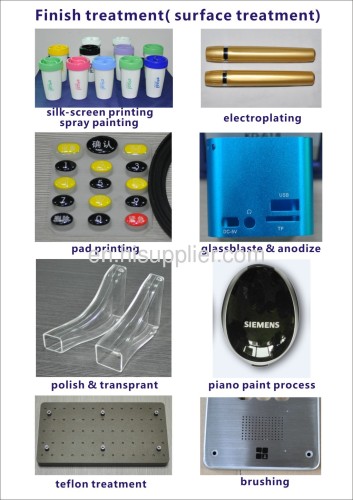

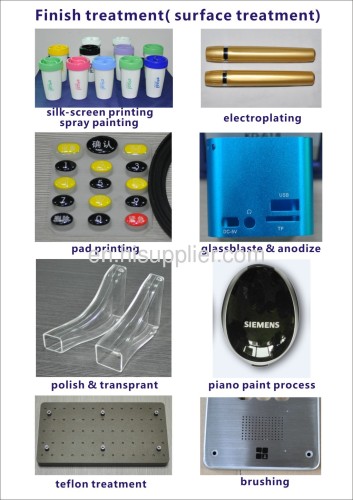

3, finish treatment(surface treatment)

If you need finish treatment(surface treatment),such as painting, screen printing, anodizing, glass blasted, pad printing, electroplating, oxygenation, brushing, etc. please give us the details as possible as you can. Such as the colors( with Panton numbers or CMYK&RGB numbers), the size of glass, the size and the location that you want to print, etc.

If you don`t know how to prepare them, please contact us for help.

Contact us:

Address:2F,Bldg.C,Fufang S&T Park, Fuyong Town, Baoan District, Shenzhen, Guangdong, China

Tel: +86-755-27150460

Fax: +86-755-27658255

M.P.:+86-15999640890

E-mail:cwh @carful.net

MSN: carful @live.com

Skype: gavin.cwh

Website:carful.com.cn prototype-cn.com

-------------------------------------------------------------------

Gift for the business cooperation

CARFUL owned an another company that called "Carful Auto Accessories (Shenzhen) Co., Ltd.", we produce many excellent products such as Bluetooth car kit, universal hands-free mount,etc.( carful.cn ).Every customer that cooperated with us in Rapid Prototyping and

CNC processing project can get a gift from "Carful Auto Accessories (Shenzhen) Co., Ltd."

-------------------------------------------------------------------

Our factory

-------------------------------------------------------------------

Our equipment

-------------------------------------------------------------------

customers and cooperation

We have lots of customers in Europe, America, Japan and South Korea and every parts of China. Such as Siemens, Philips, Nokia, Parrot,etc.

Meanwhile, CARFUL also cooperates with some domestic companies, associations, and foreign counterparts about academic exchange, sharing the technological achievements, to keep our technical ascendant, and established a good bridge for the both sides.

-------------------------------------------------------------------

faithful service and low price, keep secret for customers:

Realize your ideas; we assure your excellence with low cost!

Over 10 years` experience, perfect after-treatment handwork!

Carful Co., Ltd. was found in 2002, adhering to the spirit of "professional, high-quality, efficient, honest ", after recent years of exertion and innovation, we has developed into a professional and experienced company that include metal and plastic model making,

rapid prototype making, small batch processing, Reverse Engineering,product and structure design, etc.

CARFUL will provide you with high quality guarantee, Efficient and competitive quotation, Your satisfaction is our greatest achievement!

Also we will keep secret for you strictly, we can sign contract separately for it.

We can accept the payment : 50 % upfront and 50% before shipment by sending photos for confirmation. So it will reduce the risk for your cooperation with us.

-------------------------------------------------------------------

What can we do?

Service and application

Carful can provide you the rapid and satisfactory service in the field of product design, prototype making, batch processing. Meanwhile we can meet your requirement of different materials, processing technology and industries.

Product design

1. RE(reverse engineering). the experienced engineers uses precision laser measuring instrument to capture the design data of one product, then complete the design of products.

2. ID(Industry Design). Through market research and analysis, we will keep constantly communicating with customers, Screening, and improving, until we get a good idea that adapts to the market and the consumer.

3. MD(Mechanical Design). On the basis of full understand of the product`s functions, compliance to appearance design, reference to the size and form of various components, we determine the most reasonable structure design.

Prototype making

The classic ideas and reasonable structure, must be ultimately verified by prototype and model. Carful uses the required materials, with the process of

CNC machining, laser rapid prototyping etc. and many technology such as grinding, polishing, fuel injection, screen printing, pad printing, laser engraving, sandblasting, electroplating, oxidation, drawing, the UV, relief etc. to complete the verification of the appearance, structure or function of your design.

1.Analyzing by processing methods, we can process the following prototypes and models :

CNC plastic prototype: with the material of: ABS, acrylic, PP, PC, POM, nylon, wood, etc;

CNC metal prototype: with the material of:aluminum, aluminum - magnesium alloy, aluminum - zinc alloy, copper, steel, iron, etc;

Rapid Tooling: rapid metal tooling, silicone molding, low-pressure pouring mould

Hand-carved making: with the material of: fatlute, foam, plaster, and so on.

2. Analyzed by application, we can process the following prototypes and models :

automobile components prototypes: automobile and motorcycle parts, car dashboard, shade and other parts;

medical devices prototypes: x-ray, blood dialysis device, monitor, foot care boxes

Household appliances prototypes:such as color TV, air conditioning, electric fans, electric oven, monitors, kettles, coffee makers, electric fans, electric cooker, juicer, Blender, etc.

Digital telecom prototypes:such as mobile phones, telephones, fax machines, doorbell, cameras and others

Small batch processing

In industrial production, because of the different processes, costs, quantities, there are many parts that can`t use mass production by machines, which require a certain special technology to manufacture them with small batch. also they may need manual processing. We mainly use CNC to do the small batch processing.

1. Small batch processing of plastic parts , with the material: POM, ABS, transparent acrylic (commonly known as PMMA), PC;

2. Small batch processing of

metal parts, with the material: aluminum, aluminum - magnesium alloy, aluminum - zinc alloy, copper, steel, iron, etc.